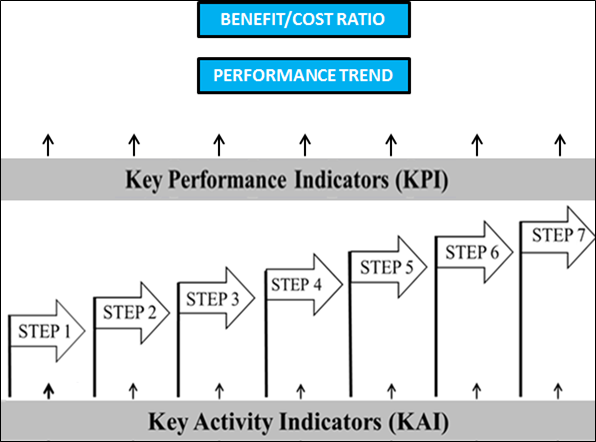

Good for professionals working on the implementation of WCM within Manufacturing sectors DOCUMENT DESCRIPTION This presentation provides the details behind and the 11 pillars of World Class Manufacturing (WCM) Got a question about the product?The 3 Pillars of WorldClass Maintenance A ll operations managers know the great importance of being able to meet their organization's increasing expectations for reliability, lower costs and higher uptime Admittedly, some do try to build a differentiator by focusing exclusively on building and tracking financial key performance indicators (KPIs)Adopting World Class Manufacturing Practices does not require huge investments in Hi Tech machines or equipment or something like that!

World Class Manufacturing Ppt Lean Manufacturing Business

World class manufacturing ppt free download

World class manufacturing ppt free download-Adopting World Class Manufacturing Practices does not require huge investments in Hi Tech machines or equipment or something like that!World class manufacturing is a group of concepts, which develops standards for production and manufacturing for another organization to follow Japanese manufacturing is attributed for revolving the notion of worldclass manufacturing World class manufacturing was introduced in many sectors like automobile, electronic and steel industry

World Class Manufacturing

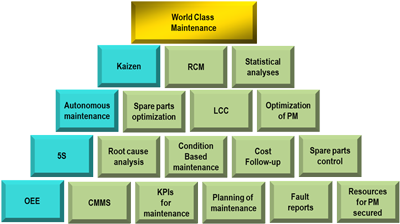

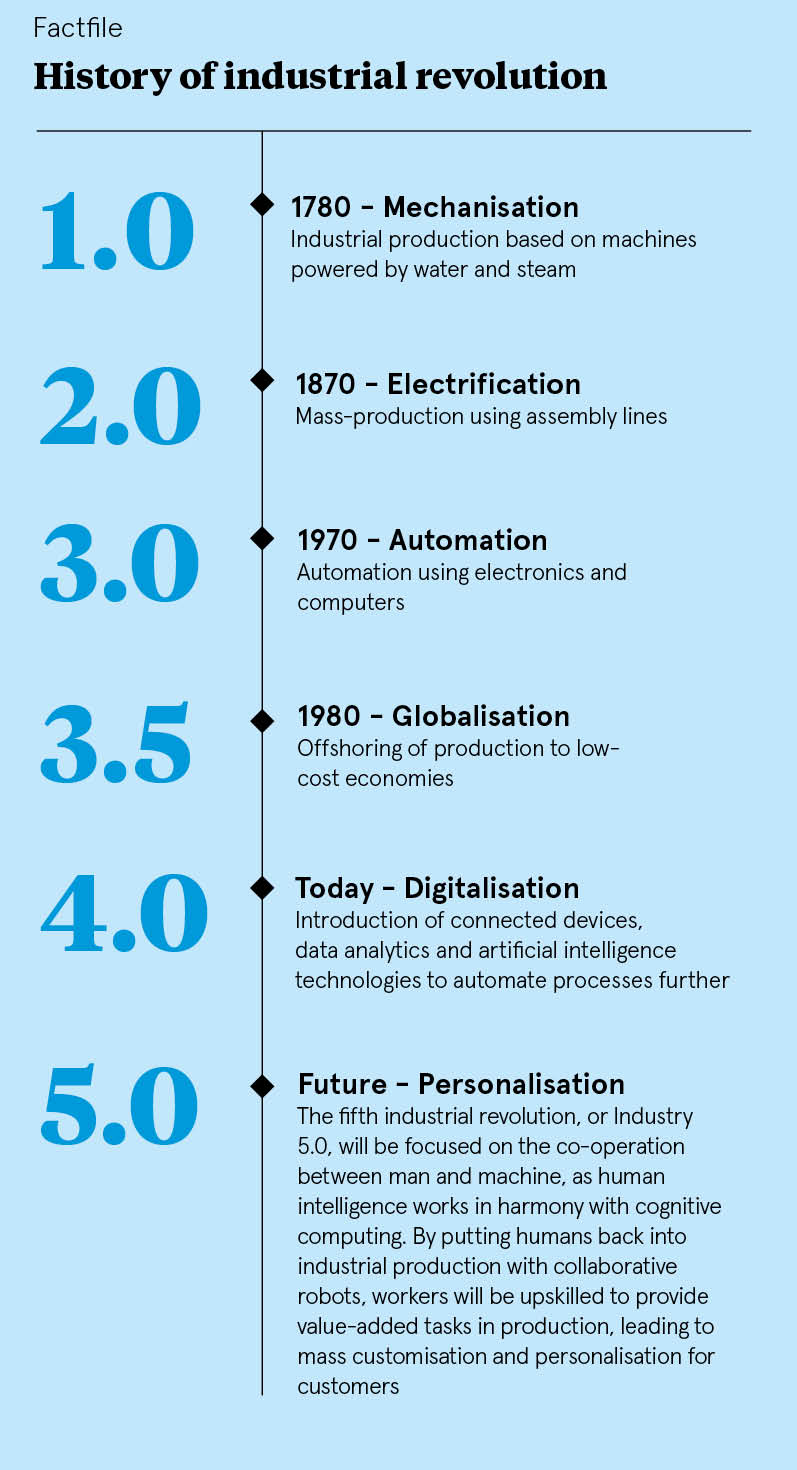

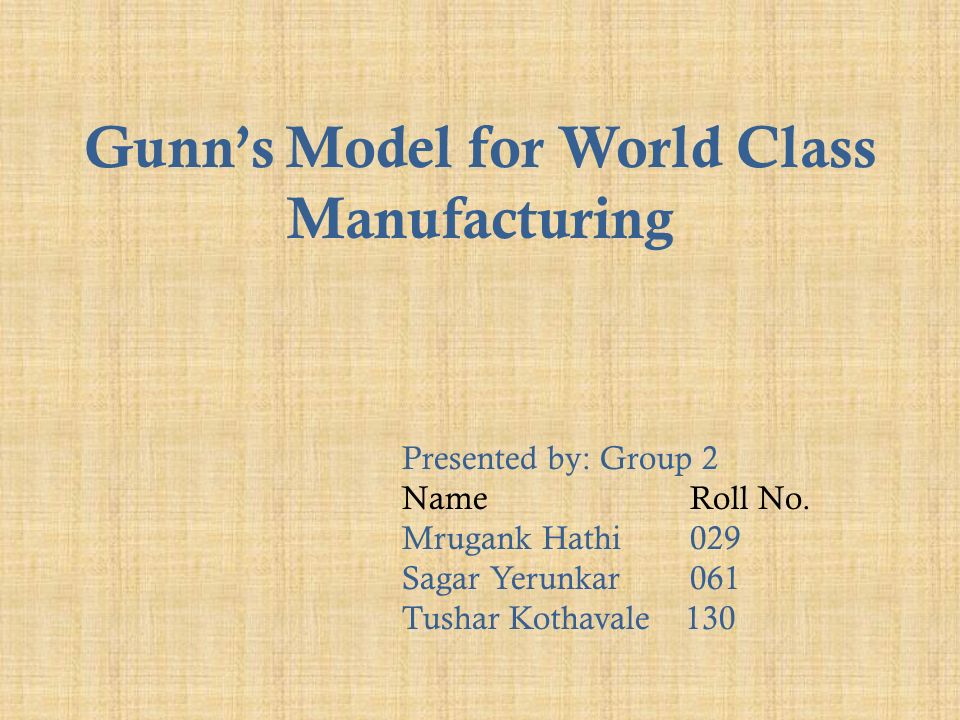

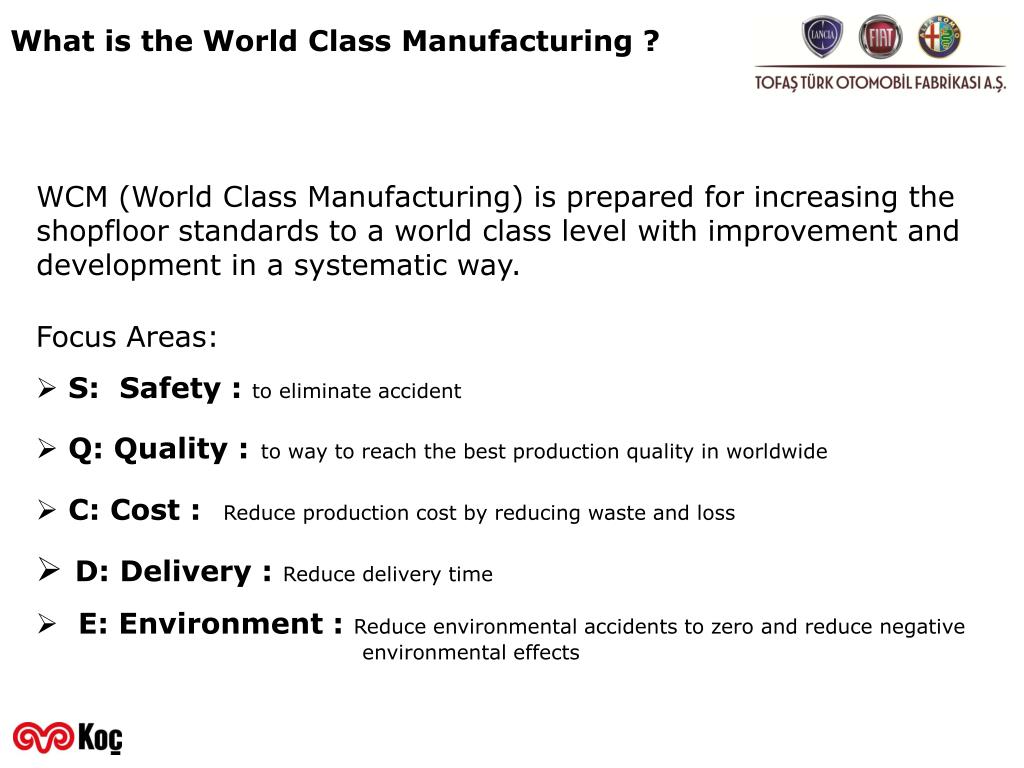

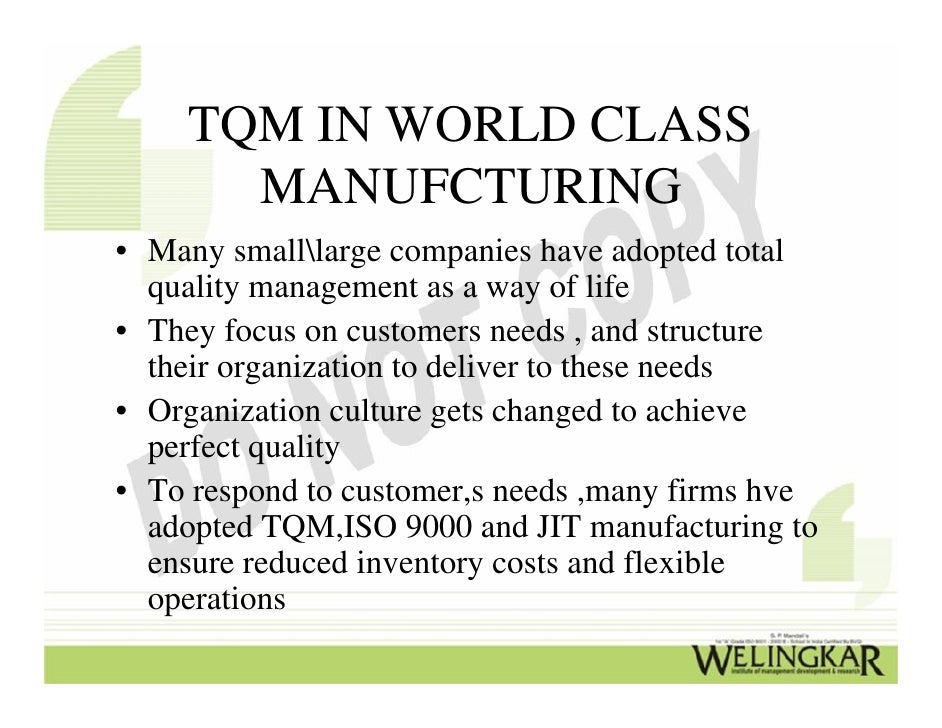

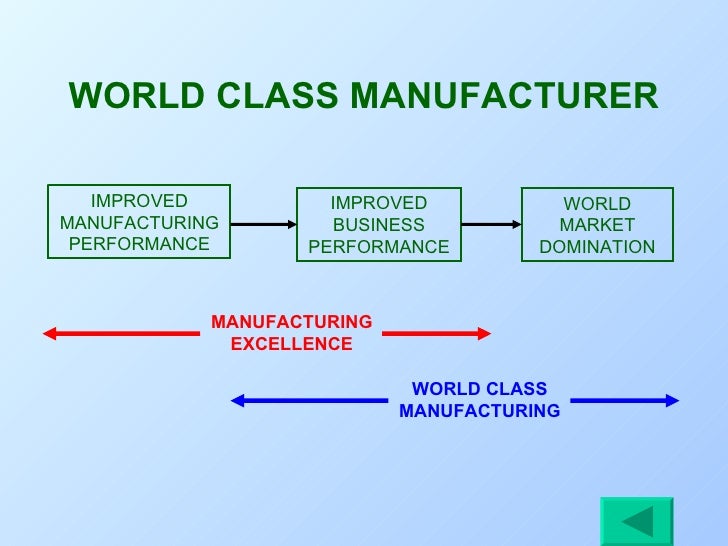

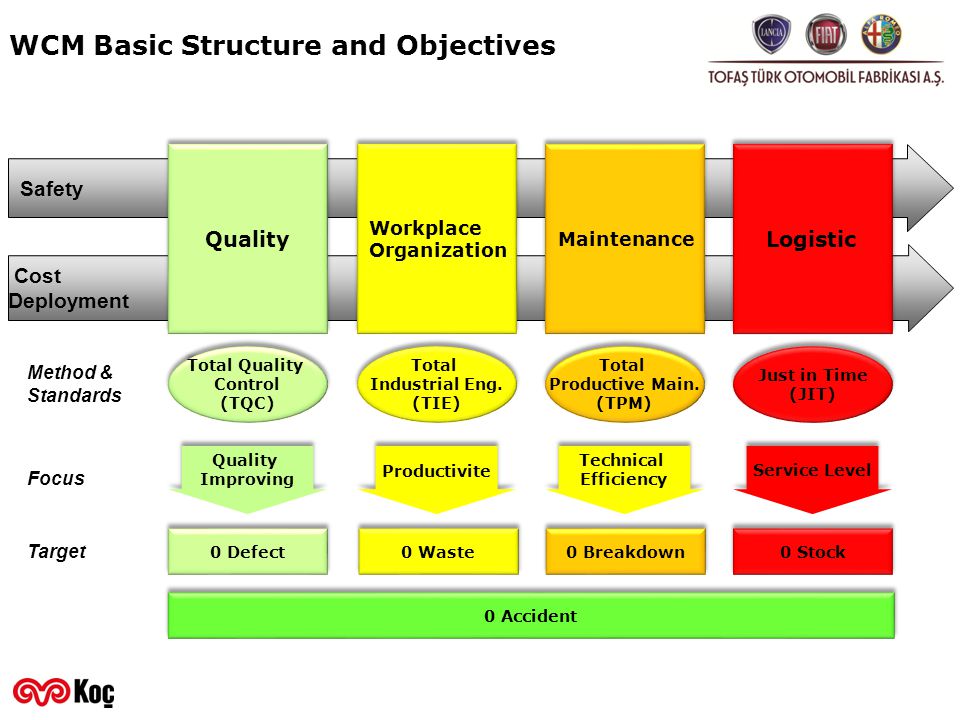

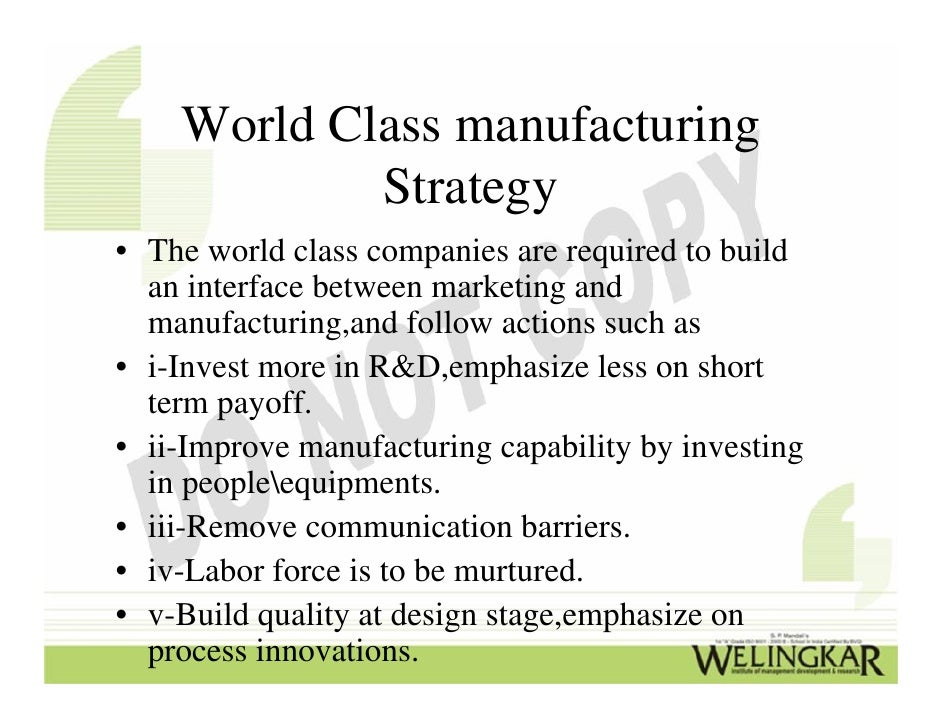

World class manufacturing is a collection of concepts, which set standard for production and manufacturing for another organization to follow Japanese manufacturing is credited with pioneer in concept of worldclass manufacturing World class manufacturing was introduced in the automobile, electronic and steel industryWorld Class Manufacturing is a set of concepts, policies, techniques, and principles for operating and managing a manufacturing company The concept of World Class Manufacturing is based on the positive results achieved by Japanese manufacturing companies after World War II A common definition of World Class Manufacturing is when United StatesAccording to Gunn (1987), WorldClass manufacturing rests on three pillars namely Computer integrated manufacturing (CIM), total quality control (TQC) and justintime (JIT) production methodsThe main objective of this paper is to enumerate the basic concepts, principles, benefits and barriers of world class manufacturing practices

Good for professionals working on the implementation of WCM within Manufacturing sectors DOCUMENT DESCRIPTION This presentation provides the details behind and the 11 pillars of World Class Manufacturing (WCM) Got a question about the product?Abstract The World Class Manufacturing (WCM) is a contemporary concept that is applied by the world leaders in the business In this concept, one of the nine pillars is directly related to theWorld class manufacturing is the philosophy of being the best, the fastest, and the lowest cost producer of a product or service It implies the constant improvement of products, process and service to remain an industry leader and provide the best choice for customers, regardless of where they are in the process

World Class Manufacturing (WCM) headlines From Turin they remark that the essential element in order to have everything working well is the human component, since without full involvement of the workers nothing could be madePpt Lean Jit Kaizen World Class Manufacturing Toyota Production Http Www Pitt Edu Edindex Officexptutorials Lesson9xp Pdf Ppt Lean Jit Kaizen World Class Manufacturing Toyota Production Order Of Operations Math Ways Order Of Operations Google Slides Make Engaging Presentations With Indesign Adobe Creative CloudAll that it requires is a change in mindset So, even small and medium manufacturers can become World Class Manufacturers

Opl One Point Lesson Template Free Download Continuously Improving Manufacturing

Wcm World Class Manufacturing And Its Applications In Plant Improvements

It's the reason why over 80% of TED presenters use PowerPoint slides (or Keynote for a MAC) – they need to make the maximum impact in only about 18 minutes Over 80% of TED presenters use slides The trouble happens when slides are slapped together and tacked onto a presentation last minute, rather than being designed as a part of the messageEmail us at email protected or ask the author directly by using the form to the rightMany use consultants for training in the SMED method If you prefer a doityourself alternative please consider our PowerPoint presentation complete with trainers manual and workshops Follow this link for a free demo

Tpm Improves Equipment Effectiveness Lean Production

Tpm And Lean Maintenance

4 Japanese Institute of Plant Maintenance Established in 1969 NonProfit, Government Organization linked to Ministry of Industry and International Trade Develops and promotes TPM Since 1971 auditing and presenting awards for TPM Achievement (since 1991 Internationally) Audits are a Stepwise process with a progression of awards levels (5 inWorldclass manufacturers are concerned with whether their operations systems have the ability to meet design specifications, rather than with evaluating the quality and quantity of products after the fact In order to attain worldclass status, the manufacturing firm has to be given the proper resourcesMany use consultants for training in the SMED method If you prefer a doityourself alternative please consider our PowerPoint presentation complete with trainers manual and workshops Follow this link for a free demo

Leadership Powerpoint Presentation Slides Powerpoint Presentation Pictures Ppt Slide Template Ppt Examples Professional

World Class Manufacturing Ppt Ppt Powerpoint

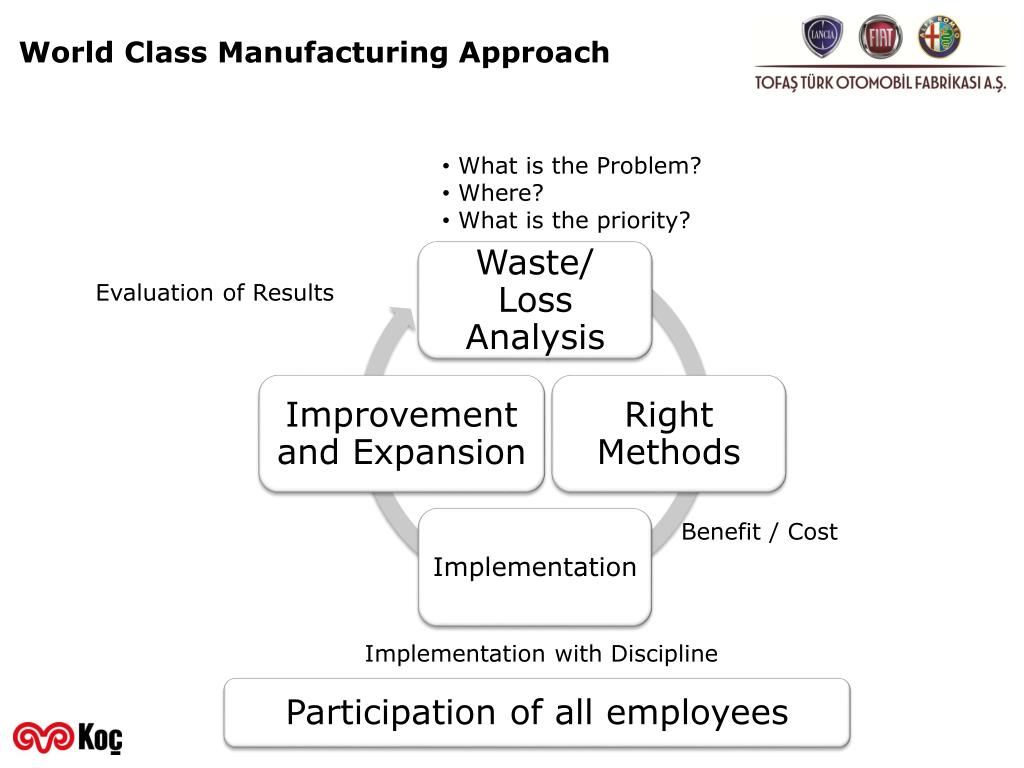

Source Schoenberger RJ(1986) – World class manufacturing the lessons of simplicity applied The current model It will be Professor Yamashina, who from 1995 3 , then through various works, especially at Fiat 4 will develop the current recognized model of the WCM system It consists of 10 technical pillars and 10 managerial criteria represented as a houseSaniflow Hand Dryer Corp is manufacturing world class, highquality hand dryers since the last 40 years and satisfying customers' needs excellently With innovative designs, the hand dryers have added to the aesthetic appeal of the washrooms in various places The process of designing and manufacturing the hand dryers takes place inhouseBeing worldclass is not enough;

Ppt World Class Operations Programs Powerpoint Presentation Free Download Id

World Class Manufacturing 35 Slide Powerpoint

All that it requires is a change in mindset So, even small and medium manufacturers can become World Class ManufacturersThe World Class Manufacturing (WCM) is an integrated system that brings the excellence of the entire logistics cycle and production of an undertaking by Continuous improvement of all services;Adopting World Class Manufacturing Practices does not require huge investments in Hi Tech machines or equipment or something like that!

World Class Manufacturing World Class Manufacturing Wcm Is A Process Which Integrates The Standalone Processes Of Jit Tpm Tqm Lean Manufacturing Ppt Download

World Class Manufacturing World Class Manufacturing Wcm Is A Process Which Integrates The Standalone Processes Of Jit Tpm Tqm Lean Manufacturing Ppt Download

As a result, multinationals now generally apply a mixture of logistic, quality and productivity oriented improvement methods, eg LeanSix SigmaTPM This combined approach is often called World Class Manufacturing of WCM, a term popular for already thirty years to describe several mixed continuous improvement approachesInvolvement of all levels and functions;Acknowledgement courses aim to create a World Class culture among the production plants The catalogue covers all main chapters of World Class Methods & Tools with the goal to increase the knowledge and develop participants' ability in identifying and reducing loss and waste Workshops to support Kaizen Projects aim to develop specific World

Operations Management Ppt And Pdf Free

Industry 5 0 What Is It And What Will It Do For Manufacturing

The term 'World Class Manufacturing' was first used by Hayes and Wheelwright in 1984 Hayes and Wheelwright described world class manufacturing as a set of practices, implying that the use of best practices would lead to superior performance 3 The term "WorldClass Manufacturing" was firstConsistent with the Shingo Principles of continuous improvement, the World Class Manufacturing (WCM) training program is designed to train individuals to improve employee morale, individual and company performance and company profits at all levels of the organization by highlighting value and nonvalue added activities and eliminating all forms of wasteAll that it requires is a change in mindset So, even small and medium manufacturers can become World Class Manufacturers

World Class Manufacturing Wcm

World Class Manufacturing Information And Free Guides

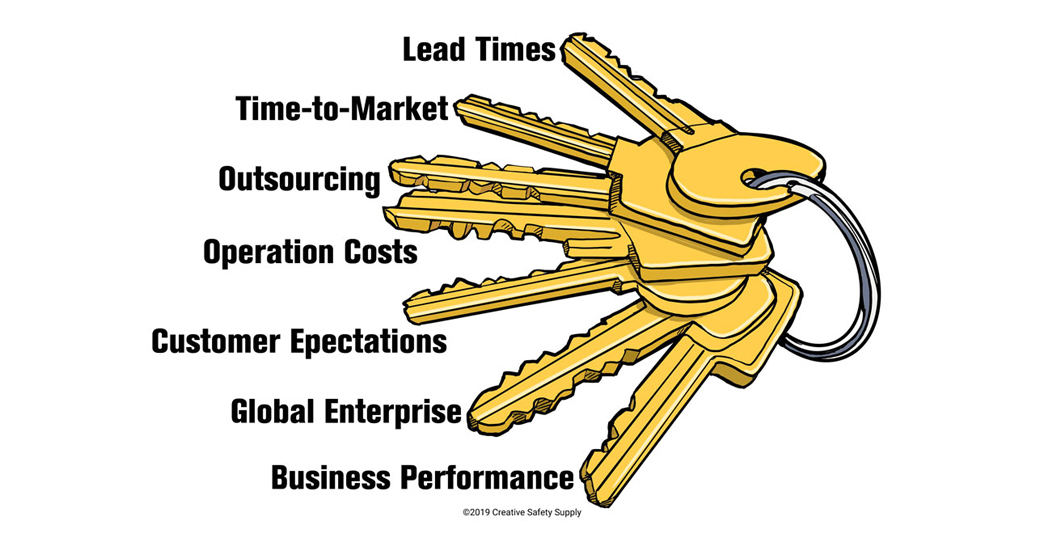

A company also has to have the capability to switch gears—from, for example, rapid product development to low cost—relatively quickly and with minimal resourcesBarbara B Flinn, Roger Schroeder "World class manufacturing an investigation of Hayes and Wheelwright's foundation" Journal of Operations • Management (17 1999) • 4 Linda C Hendry, "Applyng World Class Manufacturing to maketoorder compagnie problem and solutions" Lancaster University UKIn current global and competitive age, it is very important for organization to have manufacturing practice which is lean, efficient, costeffective and flexible World class manufacturing is a collection of concepts, which set standard for production and manufacturing for another organization to follow Japanese manufacturing is credited with pioneer in concept of worldclass manufacturing

Toyota Production System Asq904 Org Powerpoint Presentation Free Online Download Ppt U2hy9y

World Class Manufacturing Ppt Vyly2xv3mv4m

KeyWords World Class Manufacturing, Workplace Organization, Cost Deployment, Lean management 1 Introduction The present work is focused on the World Class Manufacturing, an innovation program based on Continuous Improvement, that provides the elimination of all types of waste and loss of production through theWorld class manufacturing (wcm) 1 World Class ManufacturingByDeepti Anand (066)Rahul Hedau (073)Amit Sharma (080)Shilpa Sharma (087)Komal Sachan (094)Kanad Kale (101)Manisha Mishra (108)Ritika Mittal (115)Tushar Mehta (122) 2 Definition• Aiming to compete for quality on a world wide market and becoming competitive in global market• AEmail us at email protected or ask the author directly by using the form to the right

Gunn S Model For World Class Manufacturing Ppt Video Online Download

Powerpoint Slide Mary J Peng

You can explore the rest of our site to browse through more than 700 free articles and 0 videos to enhance your presentation skills and PowerPoint skills RelatedHow to Summarize Presentations Return to Main Presentation Design Essentials Page Return to Top of World Class Business Presentations PageManufacturing Media WorldClass Presentation Experts Share Their Top Tips The "Notes" view of PowerPoint allows you to create a full blown document within the presentation withoutA shorterterm possibility is to consider the trade off between leadtime and stock variety This is a method of reducing end product variety (SKU's) stocked by deliberately stocking common sub

World Class Manufacturing

Powerpoint Presentation Design Ppt Design Company Presentation Services

Hello Friends, This is a awesome ebook on World class manufacturing for all the student pursuing management courses or MBA This ebook is in PDF format for you all to downloadYou can also find lecture notes and handouts in this section which will really help you during your examsHowever, the topics covered in this ebook are as followsThe adoption of the principles of Total Quality, LeanWorld class manufacturing is a group of concepts, which develops standards for production and manufacturing for another organization to follow Japanese manufacturing is attributed for revolving the notion of worldclass manufacturing World class manufacturing was introduced in many sectors like automobile, electronic and steel industry

Increase Manufacturing Production Capacity Vorne

Amway Business Plan Ppt 16

The PowerPoint PPT presentation "Lean=JIT=Kaizen=World Class Manufacturing=Toyota Production System" is the property of its rightful owner Do you have PowerPoint slides to share?As we explored last time, the process of becoming a World Class Manufacturing (WCM) organisation is similar to becoming a World Class F1 winning team Both require an unwavering commitment to excellence and continuous improvement from every member of the organisation (Admittedly there are fewer giant bottles of champagne when Manufacturing Organisations reach the WCM podium, but the sense ofFrom this point of view, World Class Manufacturing is a "key" concept This is the reason why the concept constituting "World Class Manufacturing" has received considerable attention in academic literature, even though it has been developed principally in relation to the needs of larger scale manufacturing organisations

World Class Manufacturing World Class Manufacturing Wcm Is A Process Which Integrates The Standalone Processes Of Jit Tpm Tqm Lean Manufacturing Ppt Download

World Class Manufacturing Ppt Vyly2xv3mv4m

Quantifying world class Instead Oliver et al 7 observed that to qualify as world class, a plant had to demonstrate outstanding performance on both productivity and quality meas‐ ures Summing up we can state that the term WorldClass Manufacturing (WCM) means the pursuance of best practices in manufacturingIntroduction of World Class Manufacturing World Class Manufacturing ("WCM") is a set of concepts, set out as policies and principles developed for the operation and management of a manufacturing organization Their focus on driving the organization towards becoming a lean mean machine with costeffective and flexible operating processes It is important to understand that WCM is not just• World Class Manufacturers are those that demonstrate industry best practice Criteria There are two overriding criteria when using this checklist to judge whether your company can be regarded as World Class 1) How does the company compare with its best competition?

Ppt Wcm World Class Manufacturing Program Powerpoint Presentation Id

World Class Manufacturing Wcm

Hello Friends, This is a awesome ebook on World class manufacturing for all the student pursuing management courses or MBA This ebook is in PDF format for you all to downloadYou can also find lecture notes and handouts in this section which will really help you during your examsHowever, the topics covered in this ebook are as followsAccording to Gunn (1987), WorldClass manufacturing rests on three pillars namely Computer integrated manufacturing (CIM), total quality control (TQC) and justintime (JIT) production methodsThe main objective of this paper is to enumerate the basic concepts, principles, benefits and barriers of world class manufacturing practices WORLD CLASS MANUFACTURING PRACTICESThere are many world class manufacturing practices that help the organizations to achieve their goals more effectivelyIf so, share your PPT presentation slides online with PowerShowcom

Free Download All I Need To Know About Manufacturing I Learned In Joe S Garage World Class Manufacturing Made Simple Full

World Class Manufacturing 35 Slide Powerpoint

World class manufacturing is a collection of concepts, which set standard for production and manufacturing for another organization to follow Japanese manufacturing is credited with pioneer in concept of worldclass manufacturing World class manufacturing was introduced in the automobile, electronic and steel industryPpt Lean Jit Kaizen World Class Manufacturing Toyota Production Http Www Pitt Edu Edindex Officexptutorials Lesson9xp Pdf Ppt Lean Jit Kaizen World Class Manufacturing Toyota Production Order Of Operations Math Ways Order Of Operations Google Slides Make Engaging Presentations With Indesign Adobe Creative CloudIllustrated 91slide PowerPoint presentation 8 Workshops Trainthetrainer manual

Ppt The Manufacturing Service Industries Powerpoint Presentation Id

30 Best Manufacturing Kpis Metrics For 21 Reporting Insightsoftware

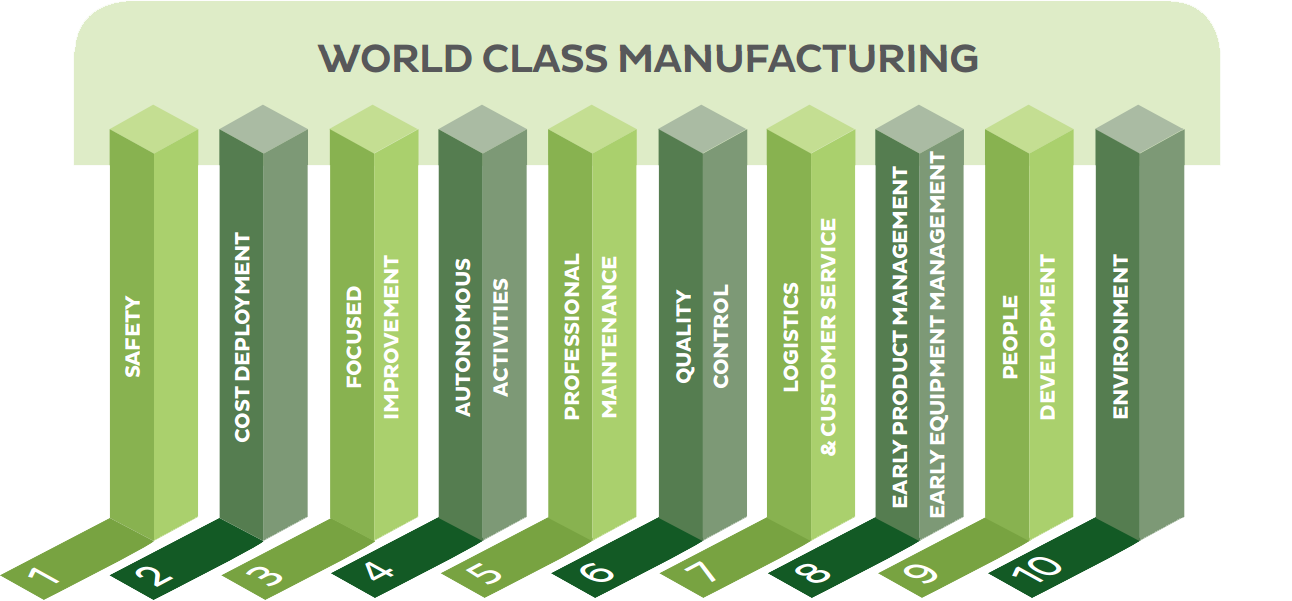

The content of World Class Manufacturing The WCM system is made up of ten technical and ten managerial pillars, illustrated as a temple (see below) The ten technical pillars are as follows 1) Safety (Occupational safety) 2) Cost Deployment (Distribution of Costs) 3) Focused Improvement 4a) Autonomous Maintenance

World Class Manufacturing 35 Slide Powerpoint

Lean And World Class Manufacturing How To Use Kaizen Getting Continiously Better For Life

World Class Manufacturing Ppt

World Class Manufacturing

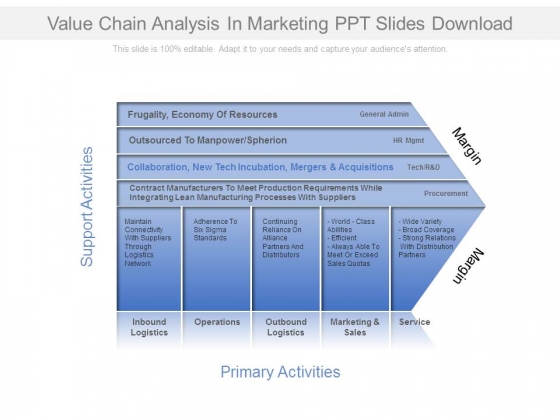

Value Chain Analysis In Marketing Ppt Slides Download Powerpoint Templates

World Class Manufacturing

Operations Management Planning And Control

World Class Manufacturing 35 Slide Powerpoint

Manufacturing Workflow Template Flowchart Diagram To Visualize The Process Flow You Can Edit This Template And Workflow Diagram Flowchart Diagram Flow Chart

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

Poka Yoke In Manufacturing Rna Automation

Worldclass Manufacturing Powerpoint Templates W Worldclass Manufacturing Themed Backgrounds

Knowledge Management And World Class Manufacturing An Initial Approach Based On A Literature Review

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

World Class Manufacturing 1 Ppt Inventory Supply Chain

Complete Guide To The Ppt Framework Smartsheet

World Class Manufacturing World Class Manufacturing Wcm Is A Process Which Integrates The Standalone Processes Of Jit Tpm Tqm Lean Manufacturing Ppt Download

World Class Manufacturing Wcm Presentation

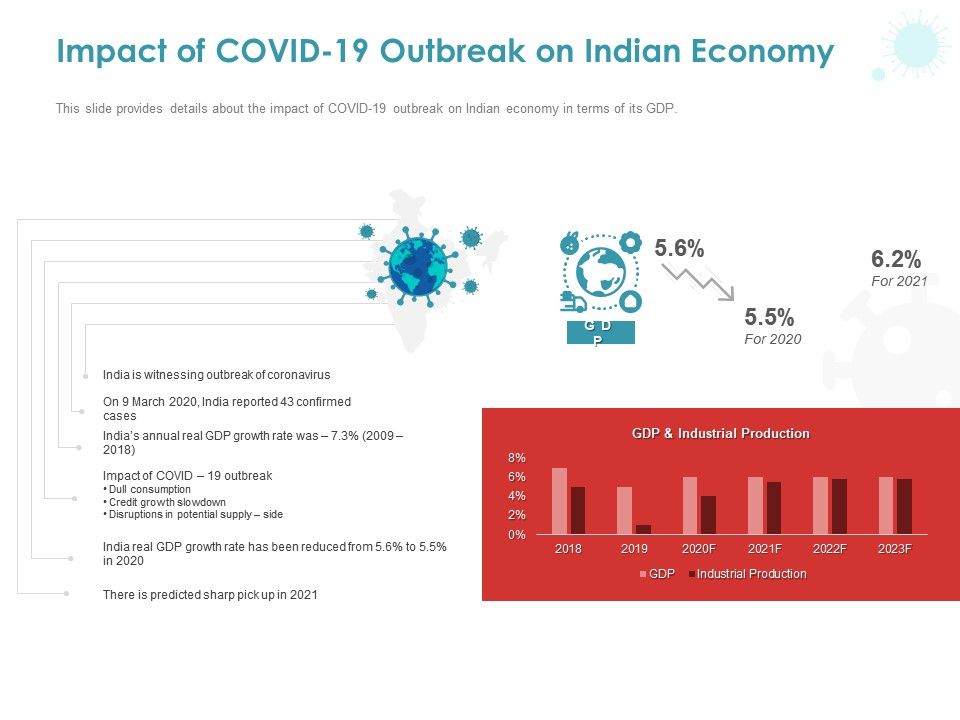

Impact Of Covid 19 Outbreak On Indian Economy Ppt Powerpoint Presentation Picture Powerpoint Slide Templates Download Ppt Background Template Presentation Slides Images

Industry 4 0 Fourth Industrial Revolution Guide To Industrie 4 0

World Class Manufacturing 35 Slide Powerpoint

World Class Manufacturing World Class Manufacturing Wcm Is A Process Which Integrates The Standalone Processes Of Jit Tpm Tqm Lean Manufacturing Ppt Download

World Class Manufacturing

Introduction Of Tablet Manufacturing Process Tablet Pharmaceutics

World Class Manufacturing

Lean Presentation Ppt Process Chart Lean Manufacturing Kanban

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

Ppt Wcm1 Prasad Jadhav Academia Edu

World Class Manufacturing

Pillars Description And Features Open Textbooks For Hong Kong

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

Ppt Lean Jit Kaizen World Class Manufacturing Toyota Production System Powerpoint Presentation Id

Artificial Intelligence Powerpoint Presentation Slides Powerpoint Presentation Designs Slide Ppt Graphics Presentation Template Designs

Ppt Ppt On Recent Trends In Automobile Powerpoint Presentation Free To Download Id 7f9a6d Odc4z

World Class Manufacturing Wcm

Ppt Wcm World Class Manufacturing Program Powerpoint Presentation Id

World Class Manufacturing Chrysler S Operational Excellence Presentations Supply Chain Innovation Enterprise

Wcm World Class Manufacturing Ppt Video Online Download

Wcm World Class Manufacturing

Lean Manufacturing Exceeding Goals Expectations Kaizen Six Sigma Lean Management Training Consulting Operational Excellence

World Class Manufacturing Ppt Lean Manufacturing Business

World Class Manufacturing Ppt Lean Manufacturing Business

Ppt Tpm One Point Lesson Powerpoint Presentation Free To Download Id 4ec5 Mdmzn

World Class Manufacturing Ppt Lean Manufacturing Business

World Class Manufacturing

Artificial Intelligence Powerpoint Presentation Slides Powerpoint Presentation Designs Slide Ppt Graphics Presentation Template Designs

The World Class Manufacturing Programme At Chrysler Fiat Co Better Operations

Improving Operations Performance With World Class Manufacturing Technique A Case In Automotive Industry Intechopen

Ppt Wcm World Class Manufacturing Program Powerpoint Presentation Id

World Class Manufacturing Ppt Lean Manufacturing Business

30 Best Finance Powerpoint Ppt Templates For Financial Presentations

World Class Manufacturing Information And Free Guides

World Class Manufacturing

Ppt World Class Lean Manufacturing Basics Addvalue Nilesh Arora Powerpoint Presentation Id

World Class Manufacturing Ppt Vyly2xv3mv4m

World Class Manufacturing Ppt Ppt Powerpoint

Proposal For Corporate Motion Picture Production Ppt Powerpoint Presentation Complete Deck With Slides Powerpoint Templates

Standardized Work Instructions

Toyota Production System Vision Philosophy Company Toyota Motor Corporation Official Global Website

Opl One Point Lesson Template Free Download Continuously Improving Manufacturing

World Class Manufacturing Ppt Quality Business Innovation

Industry 4 0 Fourth Industrial Revolution Guide To Industrie 4 0

Complete Guide To The Ppt Framework Smartsheet

7 Steps To World Class Manufacturing Ppt 7 Steps To World Class Manufacturing Competitive Edge Management Consultants What Does It Mean To Be A Course Hero

The Three Keys To Lean Transformation Success Essence Leadership

0 件のコメント:

コメントを投稿